A Promessa e o Perigo da Nova Revolução Digital

A nova corrida tecnológica global levanta uma pergunta urgente: estamos prontos para confiar na inteligência que criamos?

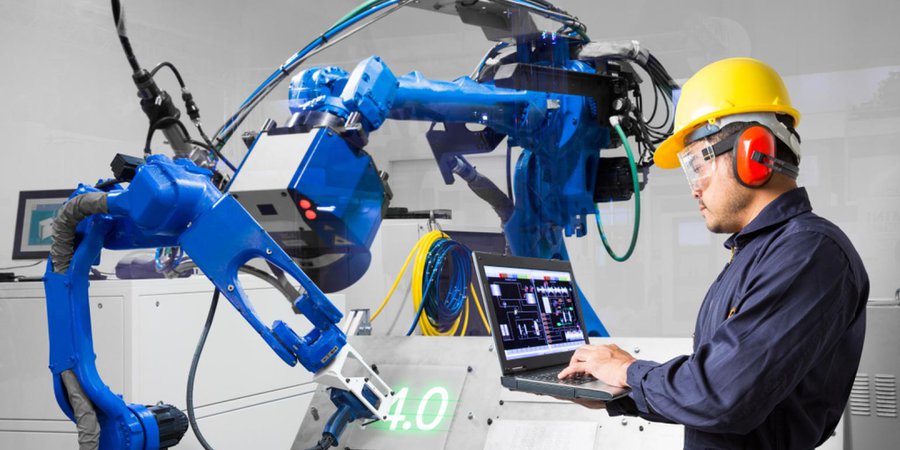

Nosso co-fundador Alexandre Del Rey, que também é professor da FIA, comenta sobre a Indústria 4.0 e seus desafios em entrevista ao portal A Voz da Indústria

A Indústria 4.0 é uma mudança sem volta. Afinal, com a chegada das tecnologias e sistemas, os negócios terão a oportunidade de tornar o processo produtivo mais eficaz e, assim, reduzir custos. No entanto, o ideal da Indústria 4.0 – com empresas totalmente integradas e autônomas -ainda é um passo que está fora da realidade do setor industrial brasileiro. Afinal, esse tipo de transformação envolve investimentos altos, mudanças profundas e qualificação de pessoas. Qual o caminho, então, para adotar a Indústria 4.0 aos poucos e melhorar a competitividade sem onerar o negócio? Continue com a leitura e descubra!

A boa notícia é que a Indústria 4.0 não é uma transformação que vai acontecer de repente. Apesar de muitas empresas já estarem se adequando há um tempo, isso não significa que só terá chances quem conseguir fazer uma virada de chave brusca.

“A adoção da Indústria 4.0 é um processo que precisa ser primeiro concebido e depois implementado. Na verdade, não é algo que acontece instantaneamente”, esclarece Alexandre Del Rey, professor do MBA Gestão Empresarial da FIA (Fundação Instituto de Administração).

De acordo com o professor, a primeira etapa desse processo de digitalização é traçar uma estratégia, considerando todos os elementos da Indústria 4.0. “O que muda no negócio, se a missão da empresa permanece a mesma, onde se quer chegar no futuro, onde as novas tecnologias como Internet das Coisas, Big Data e Inteligência Artificial podem ter impacto no negócio, processos, produtos e serviços – essas são reflexões muito relevantes”.

Feito isso, o professor recomenda o desenvolvimento de um roadmap de implementação tecnológica, para que seja possível priorizar projetos. “O que acontece, muitas vezes, é o oposto: a empresa não pensa no longo prazo e inicia imediatamente um projeto de IoT (Internet das Coisas), que se batiza como Indústria 4.0. Neste caso, não há uma transformação real e os ganhos de longo ficam limitados”.

A Indústria 4.0 não é o equivalente a jogar fora todos os equipamentos da empresa e começar do zero. Com um bom planejamento, é possível que empresas de todos os portes se adaptem e obtenham retorno ao longo do processo.

“Uma das primeiras mudanças que as empresas podem implementar é a cultura de dados. Ela é fundamental para qualquer estratégia baseada nas novas tecnologias a capacidade de coletar, processar e analisar dados”, recomenda Del Rey.

Para o professor, a cultura de dados traz mais inteligência aos negócios. Além disso, ela permite definir melhor os processos e, assim, priorizar a adoção das tecnologias da Indústria 4.0. Quando são bem definidos, é possível pensar em quais sensores podem coletar mais dados de maneira automatizada e ajudar ainda mais na eficiência e eficácia dos processos.

Del Rey ainda recomenda que as empresas participem mais de congressos sobre o tema. “Há muita falta de conhecimento do que a tecnologia pode fazer hoje e como pode ajudar a trazer mais competitividade as empresas”.

Está convencido de que a Indústria 4.0 é, sim, algo que a sua empresa pode (e deve) começar a pensar? Então, anote essas dicas para começar a implementar as mudanças sem que isso afete demais a lucratividade do negócio.

“Normalmente é preciso ter um plano de transformação. Há muitos projetos que são relativamente fáceis de implementar e que trazem ganhos praticamente imediatos. Por isso, pensar em um roadmap de transformação é a minha principal recomendação”, diz Del Rey. Com isso, é possível ter uma visão geral da empresa e identificar os projetos com custos acessíveis e de alto retorno, sendo que são eles que vão preparar o terreno para projetos de maior complexidade no futuro.

“Colocar um sensor de presença em um local de trabalho, por exemplo, pode imediatamente reduzir o gasto de energia e ser base para outros projetos que necessitam de informação de fluxo de pessoas. Escolher uma câmera digital ao invés de um sensor de presença para monitorar presença pode construir as bases para habilitar muito rapidamente funcionalidades que requerem reconhecimento facial e biometria”, esclarece o professor.

Por fim, Del Rey complementa que um plano estruturado de transformação digital fará toda a diferença nesse processo de adoção da Indústria 4.0. Afinal, há diversas opções de projetos interessantes de baixo custo e com excelentes resultados!

E você, como enxerga essas pequenas mudanças que podem levar a sua indústria a outro patamar de produção? Conte pra gente pelos comentários e até a próxima!

Conselheiro fundador da I2AI – Associação Internacional de Inteligência Artificial. Também é sócio-fundador da Engrama, sócio da Startup Egronn, e na consultoria Advance e investidor na startup Agrointeli . Tem mais de 20 anos de experiência em multinacionais como Siemens, Eaton e Voith, com vivência em países e culturas tão diversas como Estados Unidos, Alemanha e China.

Palestrante internacional, professor, pesquisador, autor, empreendedor serial, e amante de tecnologia. É apaixonado pelo os temas de Estratégia, Inteligência Competitiva e Inovação.

É Doutor em Gestão da Inovação e Mestre em Redes Bayesianas (abordagem de IA) pela FEA-USP. É pós-graduado em Administração pela FGV e graduado em Engenharia Mecânica pela Unicamp.

A nova corrida tecnológica global levanta uma pergunta urgente: estamos prontos para confiar na inteligência que criamos?

Por que dominar a IA será a nova alfabetização do século XXI

Conselhos de Administração devem evoluir da supervisão reativa para a antecipação estratégica, frente à crescente complexidade e volatilidade dos ambientes de negócios.

De 14 a 25 de julho, reserve suas manhãs das 08h00 às 09h30 para participar da tradicional Maratona I2AI! Uma jornada intensa com debates e palestras sobre temas essenciais: Ética,